In order to find a permanent printing surface for my 3d printer, I found several solutions but they all have something in common:

They are too expensive for me because of the huge printing surface. 400x250mm would be a special size and therefor they charge a special price.

While I am writing these lines my 3d printer is printing on a PEI coated sheet of glass and I have 8 more plates at beta testers.

I found a way to create a thin coat of PEI which will let your PLA stick to the glass plate like hell, if the temperature is over 50°C (122°F). Below 40°C (104°F) your Printings will become super easy to remove.

This is the story how I created the coating and how you can do it by yourself:

PEI (Polyetherimide) is a an amorphous, amber-to-transparent thermoplastic. Here in Germany it is costly with 200-400€/kg, 2016)

First i dissolved PEI in Dichloromethane (DCM)

Attention: While working with solvents like DCM wear savety gear and take care of a good airflow.

The first attempt was to cover the glass by hand and to apply the DMC-PEI-Mixture with makeup-remover-cotton. For good adhesion I cleaned the glass before with acetone:

The result was very unequally and I thought of a new technique. I choosed to apply the solvent next time by spraying:

But this time the result wasn’t that much better. The DMC evaporated before it impinged on the glass. The result was a very flaky PEI layer on the surface of the glass.

I tought it would be a good idea to bake the glass cause of the property of PEI being a thermoplast and its ability to become a fluid when heated.

Unfortunately every flaky spike burned and resulted in a very harsh surface quality. I removed all the PEI by hand and started the final treatment:

Now I will describe the actual PEI Coating procedure:

FYI: I dissolved about 15g PEI in 200ml DCM.

For this purpose I bought an especially deep baking sheed to put the solvent into it and then immerse the glass plates in the solution.

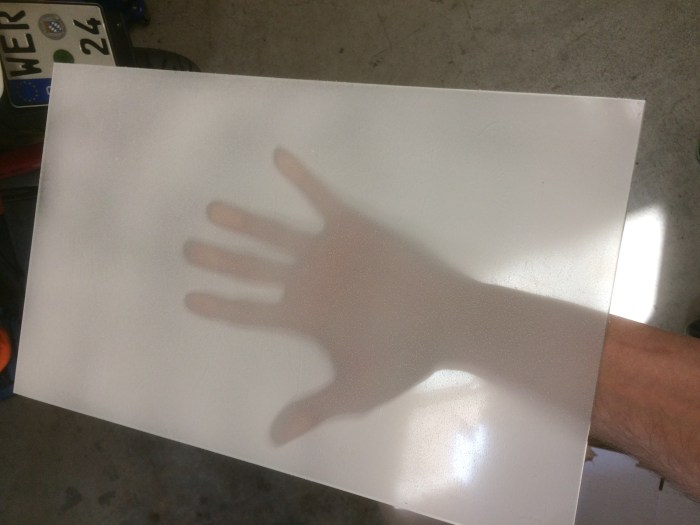

Dive the glass plate into it. After taken out of the bath and held over the grease pan for draining. A few seconds later the DCM evaporates and a thin layer of PEI remains on the glass plate.

Now great care must be taken not to damage the PEI layer, as it detaches extremely easily from the carrier plate and can be removed like film if handled improperly.

In the next step the coated glass plate is put into the not preheated oven and the PEI is baked with the grill function beyond the 250°C (482°F) mark.

After cooling, the PEI layer is firmly fused to the glass and can no longer be easily pealed off.

When the plate is heated, the adhesion between the printed parts and the layer is high enough that the plate can be lifted with a 20x20x20mm cube without separating from each other: